Guide To The Steel Ball Burnishing Process

September 27, 2021

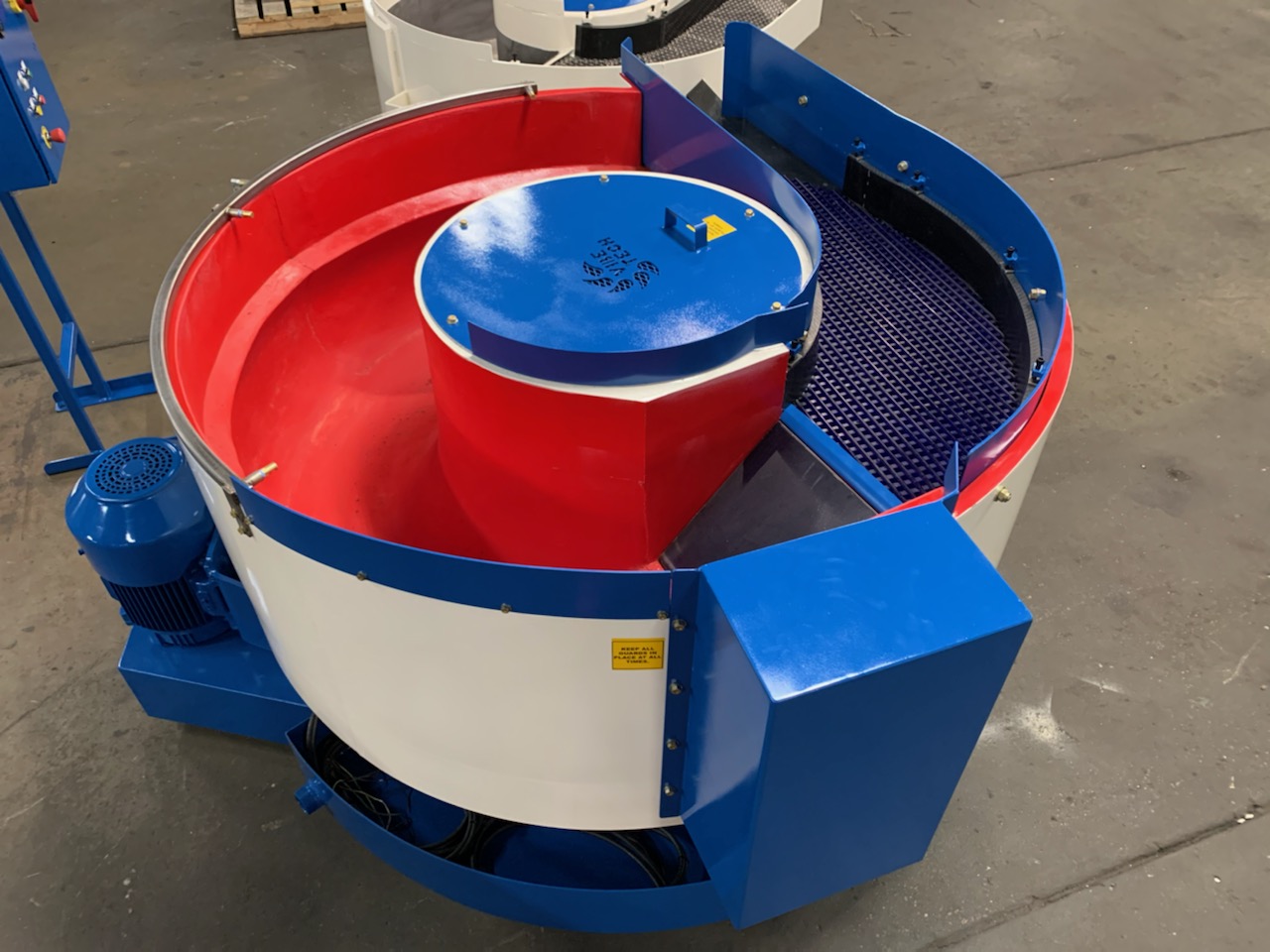

The Benefits of Hand vs. Vibratory Deburring

November 19, 2021Successfully managing an industrial facility means always striving for maximum efficiency in all business processes. If you are involved in manufacturing or parts finishing, you very well use a process known as vapor degreasing to clean parts before they are ready to transition to the next stage or go out to customers. Even if your vapor degreasing process is operating well, there is always room for improvement and there are a few ways that you might be able to optimize this process for your facility.

Tailoring the Process

The best thing you can do to help optimize your facility’s vapor degreasing process is to tailor the process specifically to each kind of job and each type of part that is being cleaned. If you have a universal setting that you use for all jobs, it is likely that it will be less efficient for some, even if it is fine for others. If you use a slightly different process for each one, tailored to that kind of part, you’ll be able to maximize efficiency for all of them. This might include tuning the time in each step, using different kinds of solvents, or more.

Honing in on Steps

Another way to optimize vapor degreasing processes is to run tests on each stage of the process and determine which ones might need tuning. Regular testing should already be a part of your preventative maintenance plan on vapor degreasing equipment and for good reason. By testing out each step individually, you may find mechanical problems or areas in the process that need work done on them in order to improve speed and effectiveness. You want to know the weak points in the system so that corrections can be made and larger problems can be detected early to prevent greater maintenance down the road.

At Mikro Industrial Finishing, we offer both vapor degreasing equipment and the solvents that they need to run any kind of job perfectly. Our experience in the field has led to an extensive knowledge of industrial processes that we can use to help offer advice and guidance as to how to best optimize your facility’s processes and be as efficient as possible. To learn more about our equipment and services, please call us any time at (860) 875-6357.