The Different Types of Glass Abrasive Media

March 22, 2021

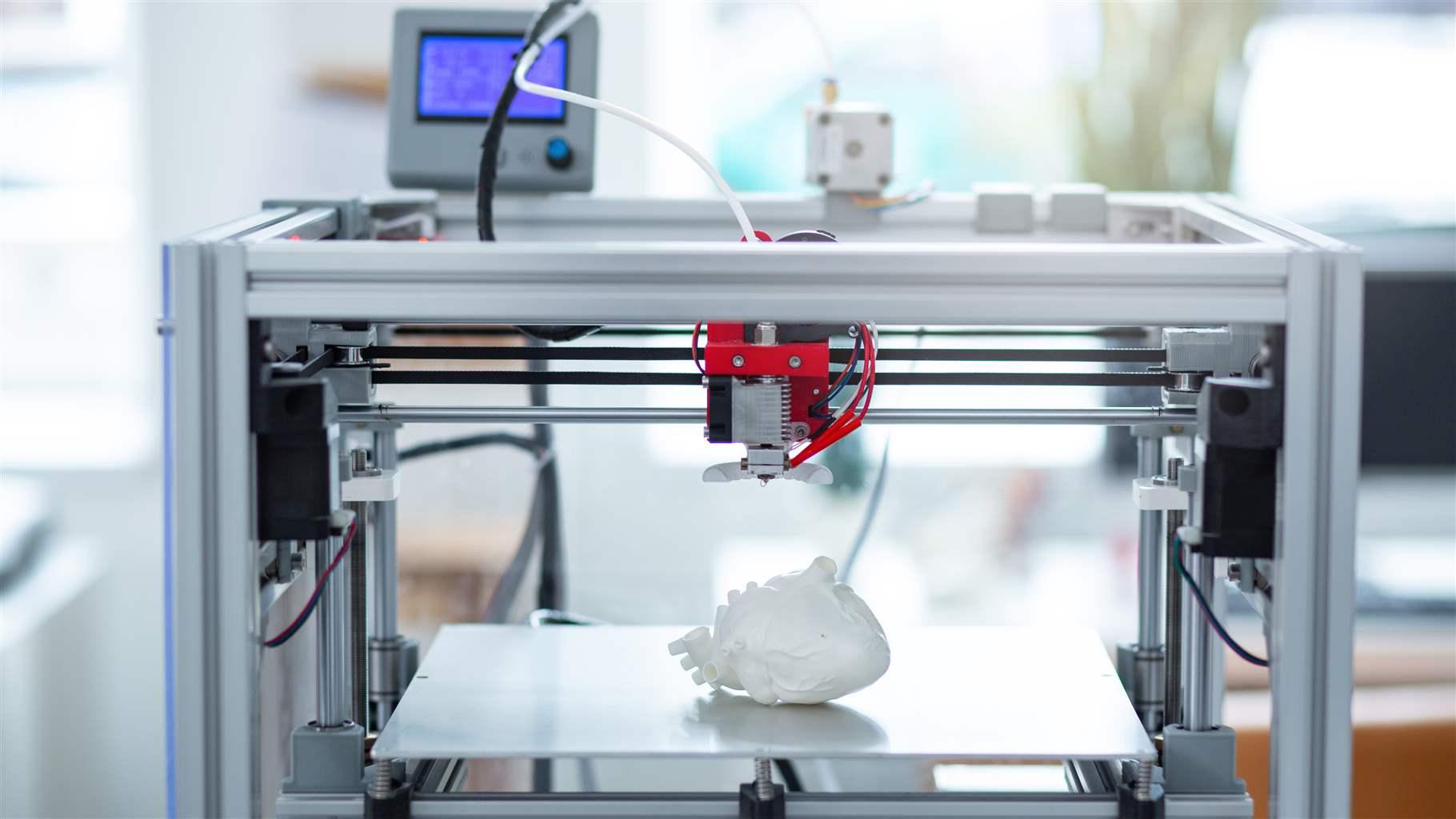

Finishing Options for 3D Printed Parts

May 11, 2021Rust is an unfortunate byproduct of aging and ill-maintained metal. While some forms of rust do naturally occur without neglect, none are desirable particularly for metal parts that are to be used in manufacturing. The removal of rust is one prominent reason that finishing processes are necessary and useful for preparing pieces for the next stage of production. Whether it is for refurbishing old, rusted workpieces or creating new ones, vibratory finishing can be done to ensure that all metal parts are clean and perfectly usable.

Mass Vibratory Finishing

The most notable benefit to vibratory finishing is that it can be used to polish metal parts en masse. Unlike hand deburring and other tedious techniques, many workpieces can be run through vibratory finishing equipment at a time and at a speed that is conductive to an industrial setting. Moreover, vibratory finishing is highly effective in wearing away not only rust, but also all other kinds of dirt and anomalies. This finishing process can be enhanced through the usage of a cleaning solvent, and while this is usually recommended, it is somewhat dependent on the type of metal that is being worked on.

The Most Efficient Methods

There are variances in vibratory finishing processes that might be best suited for old or rusted workpieces. The type of abrasive media used, for example, will make a difference in being the most effective for the type of metal parts that are being finished. Ceramic, plastic & synthetic are the most common types of tumbling media, though others can be used as the situation allows. If the workpieces are too large, a more hands-on approach might be worthwhile, although this is a more costly and time-consuming method.

Whether you are looking to restore a few old workpieces or remove the rust from many, we at Mikro Industrial Finishing have you covered. We supply equipment that is designed to execute vibratory finishing for large facilities and offer services for small batch processing for hobbyist and small business operations. For more information about our finishing equipment and the services that we offer at our Job Shop, please feel free to call us at (860) 875-6357 any time.